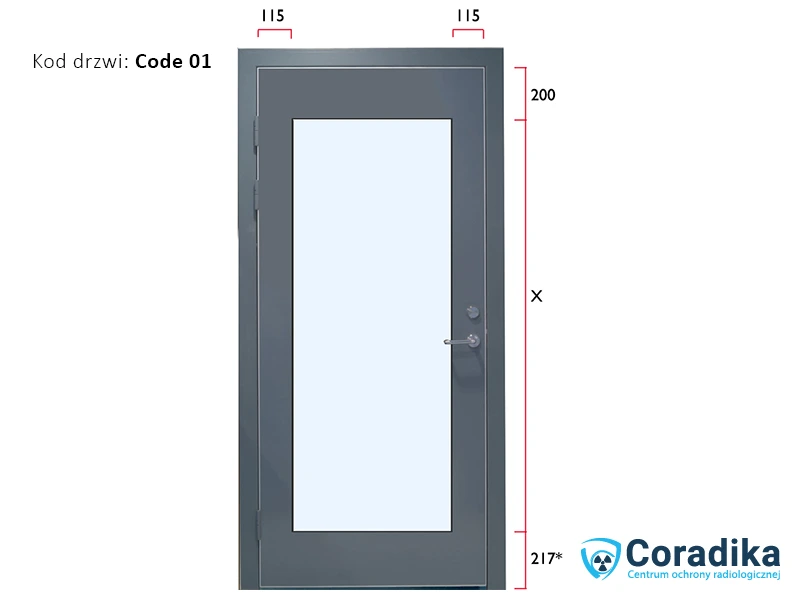

Medical doors for hospitals and healthcare facilities

Medical doors are modern solutions designed to meet the highest standards of hygiene and functionality in medical environments. With their robust construction, durable materials, and ease of cleaning, they are ideal for sterile settings such as hospitals, clinics, and laboratories.

Construction of medical doors

Medical doors feature a well-thought-out design that combines aesthetics with functionality.

- Surface material: The outer layer is made of polyester reinforced with fiberglass, available in various colors from the RAL palette.

- Door core: The core of the door is filled with a composite material, ensuring lightness and durability.

- Door frame: Constructed from anodized aluminum or stainless steel, it is corrosion-resistant and easy to clean.

Functionality and hygiene

Medical doors are designed to support the maintenance of sterile working conditions. Their key functional features include:

- Smooth surface: Ensures easy cleaning and resistance to disinfectants.

- Moisture resistance: The materials used make the doors resistant to moisture, preventing deformation.

- Compatibility with additional accessories: Such as door closers, access control systems, or window panels.

Advantages of medical doors

- Hygiene and easy maintenance: Surfaces resistant to cleaning and disinfecting agents.

- Aesthetics and color variety: The option to choose door colors from the RAL palette allows for seamless integration with the facility’s interior.

- Versatility and durability: Perfectly suited for various medical environments thanks to their robust construction.

Medical doors are a reliable solution for healthcare facilities, combining aesthetics, durability, and functionality. With the ability to be tailored to individual user needs, they represent an investment in safety, hygiene, and the comfort of daily operations.

Difference between medical doors and radiological doors

- Radiation protection: Radiological doors contain a lead layer, providing protection against ionizing radiation. Medical doors lack this feature, as they are intended for general medical use where radiation protection is not required.

- Material and insulation: Medical doors, such as ID-M, are made from fiberglass and polyester with polyurethane insulation, making them lightweight and easy to clean. Radiological doors, on the other hand, often have a more robust structure due to the protective lead material, ensuring an effective barrier against radiation.

- Application: Radiological doors are designed for areas exposed to radiation, such as X-ray or CT rooms, whereas medical doors are more versatile and used in general medical spaces, such as hospitals, clinics, and laboratories.

Technical properties

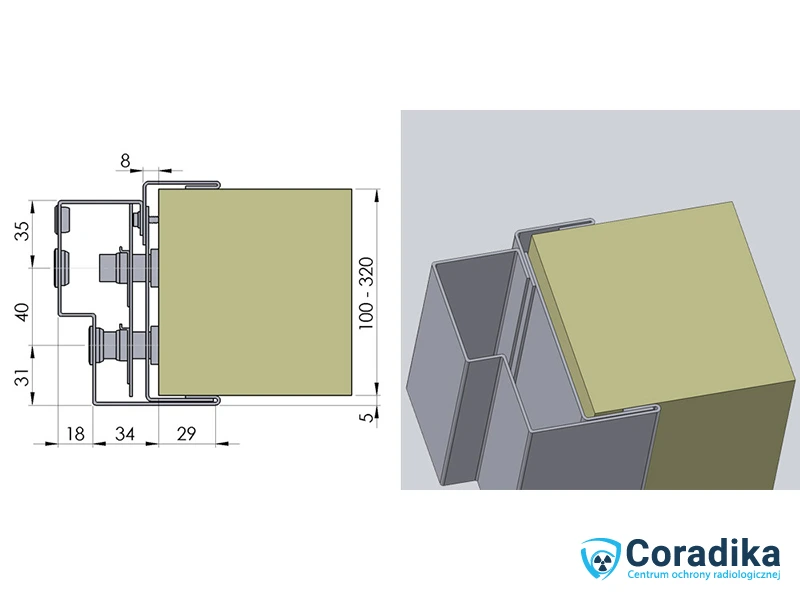

- Frame made of anodized aluminum.

- Wall thickness of the frame ranges from 74 mm to 200 mm, allowing adaptation to various wall thicknesses.

Available frame options:

- ID1: Lining on one side.

- ID2: Lining on both sides.

- The door leaf has a thickness of 40 mm.

- The external surface is made of polyester reinforced with fiberglass (standard color RAL9010).

- The door leaf profile is made of anodized aluminum.

- The core of the door leaf is freon-free polyurethane.

- Hinges: Dorma 4005 model.

- Lock case: ASSA 565.

- Door leaf in stainless steel version.

- Frame made of stainless steel.

- Other laminate colors: RAL7005, RAL7035, RAL7038, and RAL9002 (other colors can be painted using the RAL system).

Kick plate, window of any size. - Manual or automatic door closers, electric locks, or escutcheons.

- Self-pickup

- Shipping priced individually