What are the 3.1 certificate and EN 12588 standard and why they matter

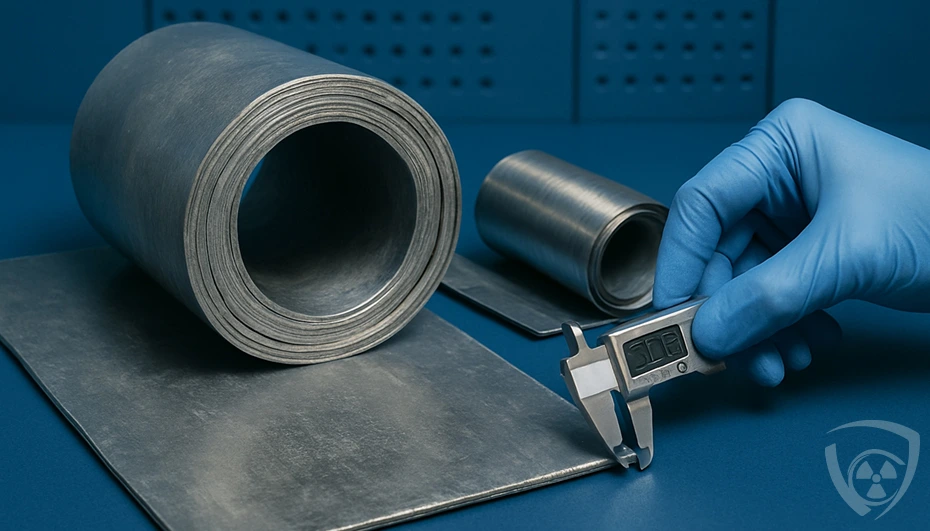

Lead sheets and foils are essential materials used in radiation protection, industry, construction, and other fields where a barrier against ionizing radiation is required. However, their effectiveness and safety depend not only on thickness but also on material quality, chemical purity, and compliance with applicable standards. In this context, the presence of a 3.1 certificate according to PN-EN 10204 and compliance with the EN 12588 standard are crucial. In this article, we explore what these documents mean and why they matter.

What is the 3.1 certificate according to PN-EN 10204?

3.1 Certificate – Definition and Use

The 3.1 certificate (Inspection Certificate 3.1) is a document issued by the manufacturer based on internal tests and quality analyses of the material. It complies with the European standard PN-EN 10204 and confirms that the product was made in accordance with the technical specifications in the order and meets the required quality standards.

What does a 3.1 certificate include?

This document contains:

- customer details,

- document number and date of issue,

- order and delivery details,

- chemical composition of the material (elemental analysis),

- compliance with applicable standards (e.g., EN 12588),

- information on thickness and lead grade.

Why is the 3.1 certificate important?

- ensures quality and consistency – the product meets the customer’s requirements,

- allows verification of chemical purity – critical in radiation protection,

- serves as a basis for further certification and technical approvals,

- builds customer trust – providing full chemical analysis and standard compliance reflects the company’s transparency and professionalism.

EN 12588 – The quality standard for lead sheets and foils

What is EN 12588?

EN 12588 is a European standard that specifies requirements for cold-rolled lead sheets.

It also applies to lead foils. This standard mainly defines:

- lead purity,

- thickness and dimensional tolerance,

- material uniformity,

- surface structure.

Key parameters according to EN 12588

EN 12588 requires:

- pure lead (Pb) content of at least 99.81%,

- limited amounts of other elements (e.g., Sn, Cu, Bi, Sb, Ni, Fe),

- proper surface structure – free from cracks, inclusions, and other defects.

Example from a Coradika certificate – Pb99.94Cu lead sheet

Coradika supplies lead sheets and foils compliant with EN 12588 and provides 3.1 certificates.

A sample certificate includes:

Chemical Composition (According to EN 12588)

- Pb – 99.94% (requirement: min. 99.81%),

- Sn (tin) – 0.0053% (max 0.05%),

- Bi (bismuth) – 0.053% (max 0.10%),

- Cu (copper) – 0.053% (max 0.08%),

- Other elements like Ni, Sb, As, Zn, Ag – in trace amounts.

Other technical details

- lead grade: Pb99.94Cu,

- basis: manufacturer’s analysis,

- reference standard: EN 12588,

- document type: 3.1 Certificate according to PN-EN 10204.

The importance of standards and certificates in radiation protection

Products used in radiation shielding, such as lead sheets and foils, must meet strict requirements.

Using uncertified material can result in:

- insufficient radiation protection,

- failure of technical inspections in medical facilities,

- health risks to patients and staff,

- non-compliance with legal regulations and sanitary requirements.

Documents such as the 3.1 certificate and compliance with EN 12588 give assurance that the material:

- zas manufactured using proper technology,

- is safe and consistent in quality,

- can be used in medical and industrial environments.

What documents should a reliable supplier provide?

Required documents list:

- 3.1 Certificate according to PN-EN 10204,

- EN 12588 compliance (e.g., confirmed by chemical analysis),

- Declaration of conformity / product technical data sheet,

- CE certificates (if applicable).

Tips for customers

- always request documentation,

- verify lead content.

Why Coradika follows the highest standards

Coradika not only supplies products compliant with current standards but also ensures documentation quality and transparency.

This means customers can be confident that the material they receive is:

- compliant with European standards,

- accompanied by full chemical analysis and technical specifications,

- delivered with an individual 3.1 certificate for each batch,

- ready for use in medical, industrial, or construction environments.

Summary

In the world of radiation protection, there is no room for quality compromises. The 3.1 certificate and EN 12588 standard are not mere formalities – they are clear confirmations that the lead sheet or foil meets high requirements in terms of purity, structure, and protective effectiveness. When you choose Coradika products, you can be sure that the materials you use are not only effective but also safe and fully compliant with legal regulations. Don’t take chances – choose certified radiation shielding solutions.